Quality Control

Quality is one of the top priorities for our team and sets us above the competition. Meticulous quality is maintained throughout our operation and the use of state-of-the-art analytical equipment. As both ISO 9001:2015 and AS9100D certified, we are well-positioned to establish strong partnerships in the aerospace and automotive industries. Our commitment to quality excellence ensures that we constantly improve in order to deliver high-quality precision machined parts on time and at a fair price.

Training and Operation – All Tri Part employees receive comprehensive training to ensure our parts meet and hold premium quality standards. Our team excels in setup, programming, and finishing processes, delivering precision machined parts exactly to customer specifications.

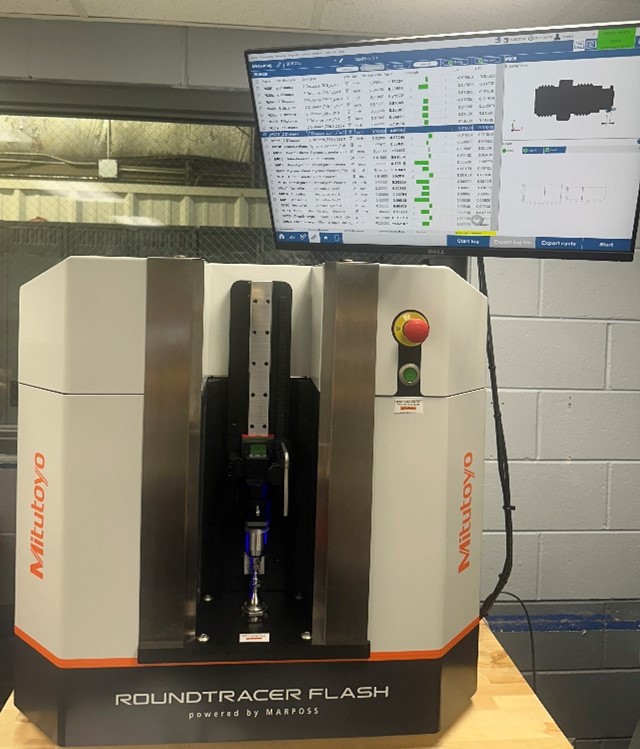

Cutting-Edge Measurement Technology – Tri Part deploys top-of-the-line precision measurement equipment to guarantee adherence to all quality standards. All equipment undergoes regular inspections to maintain accuracy and reliability. The recent acquisition of the Mitutoyo Roundtracer Flash, a first-class form measuring system, spotlights Tri-Part’s dedication to elite quality today and in the future.

Certifications – Tri Part Screw Products is fully certified to ISO 9001:2015 and AS9100D standards, and can supply all documentation for customer verification.

NEW!

Our new Mitutoyo Roundtracer Flash executes 100 static measurements in just 2 seconds!

Roundtracer Flash is based upon state-of-the-art area image sensors and it can perform many micrometric-precision checks on parts with an unprecedented speed. Roundtracer Flash uses multiple image sensors integrated into fixed positions across the product structure to cover the entire measurement range. This gives the advantage that neither the image sensors nor the part being measured must travel along the Z-axis.