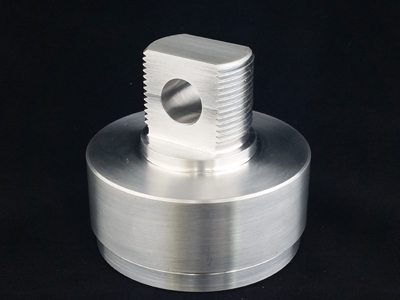

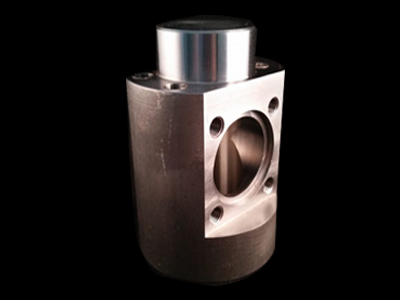

CNC VERTICAL MACHINING CENTERS

Our late model 4-axis Haas CNC Vertical Machining Centers are capable of machining the most intricate and complex parts that you might have. We offer vertical broaching for your high production needs. We also provide milling, drilling, hobbing, keyway machining, and light assembly.

Production Equipment

(2) Hass DM1 CNC w/Midaco Pallet Changer, 18 Station Tool Changer, 4-Axis | Capacity: 20″ x-axis, 16″ y-axis, 15.5″ z-axis

(1) Harding 5C Hand Screw with Turret | Diameter Capacity: 1 1/8″ | OAL Capacity: 3″

(1) Sunnen Hone Model MBC-1803 | Diameter Capacity: 2″

(1) Jet J.V.M. 942L Knee Mill

(1) KAO Ming (KM405) Tool & Cutter Grinder

(1) Cincinnati “Manual” Surface Grinder

(1) 15″ Clausing Variable Speed Drill Press

(1) Amada HA250 12″ Cap. Automatic Band Saw

(1) 12″ Tool Room Lathe